May, 2017

09:30 – 17:00 3 – 4 May

09:30 – 15:30 5 May

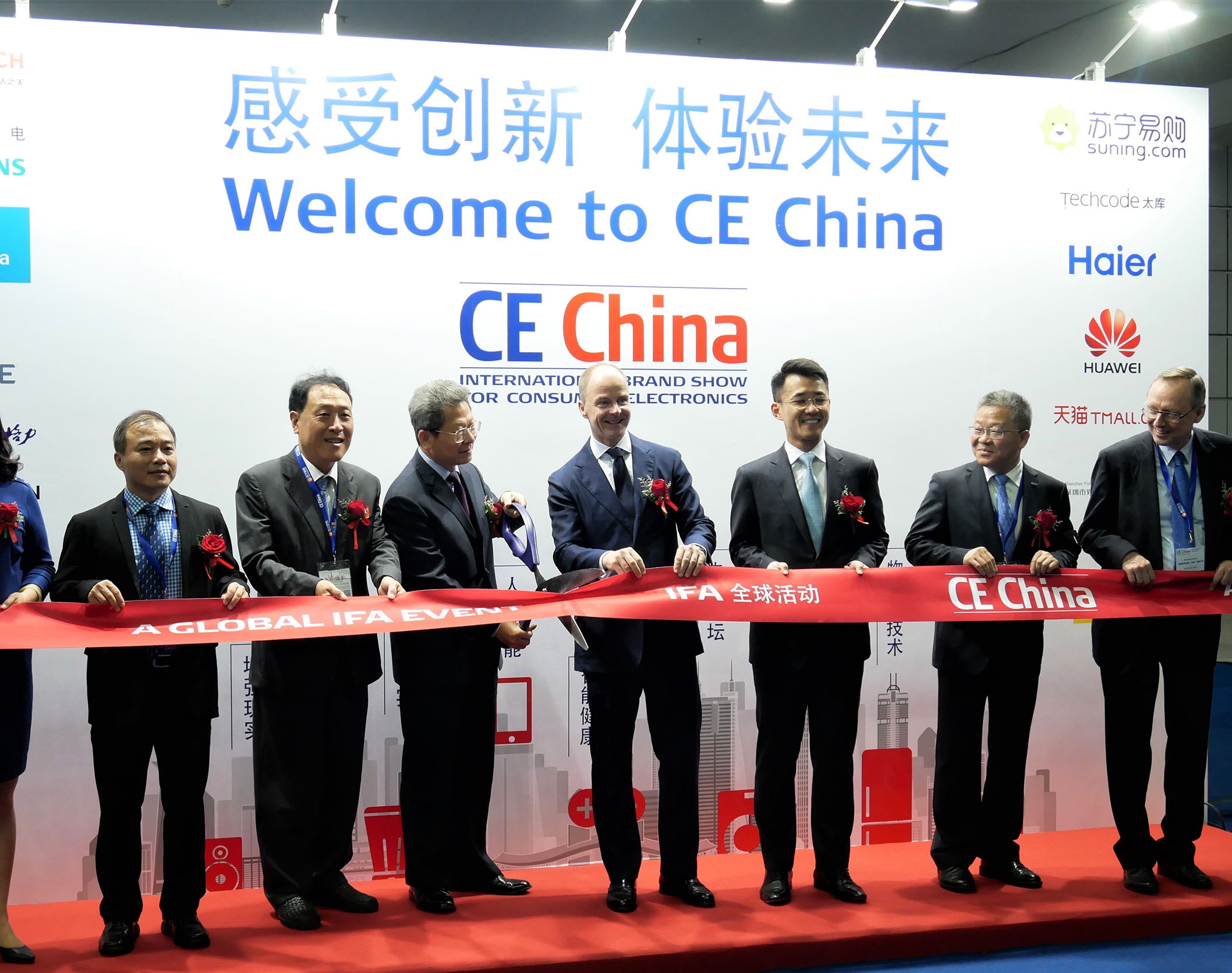

Consumer Electronics China (CE China), a global IFA event, is designed to be China’s premier trade show for consumer electronics and home appliances brands in China.

The show is a platform that unites international exhibitors with Chinese retailers who is keen to bring new products to their customers. By participating in CE China, exhibitors have the opportunity to place their products in front of valuable channel partners that can help grow sales in China as well as the rest of Asia. Not simply a technology or export fair, CE China has a strong focus on the needs of international brands, products and customers.

May 2018 is just around the corner and Shenzen is closer to your business than you might think. Be sure to reserve your place at CE China to capitalise on opportunities in the lucrative China market and beyond.

Strong Partners

CE China already succeeds in attracting leading Chinese retailers, including Suning, Alibaba and JD.COM.

About IFA

IFA 2017 has attracted more than 253,000 visitors to Berlin, as the power of innovation and brands yet again turned the event into the world’s most important tradeshow for consumer electronics and home appliances. With more than half of all trade visitors coming from abroad, IFA Berlin provided a huge boost for both manufacturers and retailers in the crucial run-up to the holiday period, which runs from Thanksgiving in the United States all the way to Christmas and the New Year. Once again, IFA was operating at full capacity, with 1,805 exhibitors showing their latest products and services on 159,000 square meters of fully booked show floor at Messe Berlin. The mood among exhibitors was highly optimistic, not least given the expected order volume of 4.7 billion euro achieved during the six days of the event.

IFA is the world’s leading trade show for consumer electronics and home appliances and will take place on the Berlin Exhibition Grounds (ExpoCenter City) from 31 August to 5 September 2018.

Q1: What is “Made in China 2025”?

A1: “Made in China 2025” is an initiative to comprehensively upgrade Chinese industry. The initiative draws direct inspiration from Germany’s “Industry 4.0” plan, which was first discussed in 2011 and later adopted in 2013. The heart of the “Industry 4.0” idea is intelligent manufacturing, i.e., applying the tools of information technology to production. In the German context, this primarily means using the Internet of Things to connect small and medium-sized companies more efficiently in global production and innovation networks so that they could not only more efficiently engage in mass production but just as easily and efficiently customize products.

The Chinese effort is far broader, as the efficiency and quality of Chinese producers are highly uneven, and multiple challenges need to be overcome in a short amount of time if China is to avoid being squeezed by both newly emerging low-cost producers and more effectively cooperate and compete with advanced industrialized economies. The English translation of “中国制造2025” — “Made in China 2025” — does capture the goal of localization, but it misses the focus on the manufacturing qua manufacturing. The plan was drafted by the Ministry of Industry and Information Technology (MIIT) over two and a half years, with input from 150 experts from the China Academy of Engineering.

Q2: What are its key contents?

A2: Based on the State Council document summarizing the plan released last week, “Made in China 2025” has clear principles, goals, tools, and sector focus.

Q3: Is “Made in China 2025” an extension of the 2010 plan to support “Strategic Emerging Industries”?

A3: The unveiling of “Made in China 2025” suggests a major departure from the Hu-Wen administration’s approach to innovation and technology upgrading. The heart of their approach was the Medium- and Long-Term Plan on the Development of Science & Technology. A 15-year plan issued in 2006, the plan’s key concept was “indigenous innovation” (自主创新) and focused entirely on advanced technologies. The culmination of the plan was the identification in October 2010 of seven “strategic emerging industries” (战略性新兴产业) that were seen as vital for China to achieve mastery in if it was to become an advanced economy. The core of the plan focused on developed leading-edge advanced technologies through investment in R&D from state and industry sources, accumulation of intellectual property, setting of distinct technical standards, and leveraging access to the Chinese market in exchange for foreign technologies. The plan set a target of SEI-related industries to account for 8% of the economy by 2015 and 15% by 2020. The plan was developed jointly by National Development and Reform Commission (NDRC) and Ministry of Science & Technology (MOST), with supplemental input from MIIT and other ministries.

“Made in China 2025” is different in multiple respects: 1) It focuses on the entire manufacturing process and not just innovation; 2) It promotes the development of not only advanced industries, but traditional industries and modern services; 3) There is still a focus on state involvement, but market mechanisms are more prominent than in SEI. For example, instead of focusing on top-down, unique domestic technical standards, the attention is on self-declared standards and the international standards system; and 4) There are clear and specific measures for innovation, quality, intelligent manufacturing, and green production, with benchmarks identified for 2013 and 2015 and goals set for 2020 and 2025. In this regard, the proposal reads much more like a five-year plan (which I believe is intentional), even though laid out over 10 years.

The plan’s language is also very different than under Hu-Wen. The term “indigenous innovation” appears only twice and “SEI” only once. There is no obvious effort to paint this as the successor to or extension of SEI, but in fact, to show that an SEI-oriented focus was too narrow and built on a misunderstanding of China’s core needs and comparative advantage. In addition, the original focus on innovation took inspiration from similar innovation programs developed in the United States, Japan, and the EU during the 2000’s in the wake of the information technology revolution and a common concern about technological competitiveness. As mentioned above, “Made in China 2025” is more consistent with how Germany and Japan approach their economies than the United States.

Although there will no doubt be problems with implementation and perhaps create new market-access challenges for multi-national companies (MNCs), from a Chinese national-interest perspective, this plan is much better conceived and more appropriate for China’s situation than the “indigenous innovation” approach and SEIs. It will be more coordinated and utilize a wider array of policy tools. If a “Made in China 2025” leading group has not already been created, I expect there to be one soon.

Q4: What are the implications for MNCs?

A4: MNCs face new challenges and opportunities with this plan. In terms of challenges, a clear goal is to make Chinese companies more competitive across the board, to localize production of components and final products, and to have Chinese firms move up the value-added chain in production and innovation networks, and to achieve much greater international brand recognition. In addition, the plan calls for Chinese firms to ramp up their efforts to invest abroad, and to do so by becoming more familiar with overseas cultures and markets, and to strengthen investment and operation risk management. (The drafters are clearly sensitive to the high proportion of failed overseas investments.) It specifies focus on the countries that together make up the Silk Road initiative, but it is meant to apply everywhere. Government measures and market incentives will be used to pursue these goals. In some ways, this represents a frontal challenge to advanced manufacturing in the US, Europe, and East Asia.

At the same time, MNCs and other countries can benefit in three ways. First, there will be greater investment and attention to the ten industries, and MNCs that align themselves with these sectors and the general goals of this plan can benefit from its focus. In some ways, there will be greater competition from Chinese companies and a buy-local push, but it’s a guarantee that MNCs will be needed to provide critical components, technology, and management for this plan is to work. Second, to the extent China genuinely embraces intelligent manufacturing, it will be much easier for Chinese companies and MNCs to collaborate, both in China and elsewhere. This is a big ‘if’, but it is potentially a way to reduce the zero-sum elements of the business relationship. And third, most broadly, if China successfully upgrades its manufacturing capacity, that will have meant it has also likely improved its overall economic governance, including its financial and fiscal systems, strengthened the education system, and increased access to varied sources of information. These should all be of general benefit to the global economy and MNCs.

Q5: How is Premier Li Keqiang’s recent tour of Latin America related to this plan?

A5: Strengthening relations with Latin America has been a priority for China’s leadership. In early 2014 Beijing announced the creation of the China-Community of Latin American and Caribbean States (CELAC) Forum, which met for the first time this January. Xi Jinping has made two trips to the region, and Li Keqiang just completed a 9-day tour of Brazil, Columbia, Peru, and Chile. Li signed dozens of agreements promoting economic cooperation, worth over $100 billion. Although Premier Li didn’t specifically tout “Made in China 2025,” he emphasized that China’s renewed focus on advanced manufacturing would be beneficial to Latin America’s economy, moving the commercial relationship’s focus away from natural resources toward basic infrastructure, industry, and information technology. Li stressed that expanded Chinese investment in everything from high-speed rail to telecom should also help Latin America upgrade its manufacturing capacity and industrial structure as well. We can expect that the Chinese leadership will continue to carry a similar message wherever their travels take them.

Scott Kennedy is deputy director of the Freeman Chair in China Studies and director of the Project on Chinese Business and Political Economy at the Center for Strategic and International Studies (CSIS) in Washington, D.C.

Critical Questions is produced by the Center for Strategic and International Studies (CSIS), a private, tax-exempt institution focusing on international public policy issues. Its research is nonpartisan and nonproprietary. CSIS does not take specific policy positions. Accordingly, all views, positions, and conclusions expressed in this publication should be understood to be solely those of the author(s).

English Underwriters Laboratories UL (Underwriter Laboratories Inc.) Shorthand .

UL safety test of America’s most authoritative , but also in security testing and identification of the boundaries of large private institutions . It is an independent , non-profit , do testing for public safety professional organizations . It uses scientific methods to study the test to determine the extent of a variety of materials , devices, products , equipment, and construction of life , property damage and whether hazards ; determine , write, issue the appropriate standards and help reduce and prevent life property losses of data , while carrying out the facts research business .

In short , it is primarily engaged in operating and safety certification and product safety certification business, the ultimate goal is to get the product to the market with considerable safety standards , guaranteed to make personal contributions to health and property safety . Product safety certification as an effective means to eliminate technical barriers to international trade , UL, to promote the development of international trade also played an active role.

UL was founded in 1894 , the initial phase of the action in maintaining UL main fire financed by the insurance sector , until 1916 , UL was completely independent. After nearly a century of development , UL has become a world -known certification body , has its own set of strict management system of the organization , standards development and product certification programs. UL by a Council to manage security experts, government officials , consumers , education , utilities , insurance and standards department composed of representatives of the daily work of the president, vice president handling . Currently , UL has five laboratories in the United States , headquartered in Northbrook town north of Chicago , and set up a corresponding laboratory in Taiwan and Hong Kong , the United States, is a symbol for consumers UL safety mark . Global , UL is one of the most trusted manufacturers conformity assessment providers.

Products have FDA approval, is the product into the U.S. market “pass.” Only FDA approved products to enter the European and American markets. The product itself, to get FDA approval, can not only improve brand influence the product, but also greatly expand the product in the international market share.

FDA certification scope

For all direct contact with food and beverages , or direct contact with human tongue containers, materials, etc. , must pass FDA standards , testing and certification , in order to enter the U.S. market.

1 FDA testing and certification of food packaging materials

Paper, plastic film, metal foil plastic

2 glass ceramic products FDA testing and certification

Various types of glass ceramic pots, bowls, plates , spoons, pots, cups, bottles, pots and other products

3 FDA food-grade plastic products testing and certification

Direct contact with the food or the plastic material entrance , including: nylon , ABS, ACRY, PU, PE, PC, PVC, PP, PR, PET, PO, PS, PSU, POM, PPS, EVA, SAN, SMM, EVA, BS, MEL, COPP, KRAT, ACRY etc.

4 . Coatings FDA testing and certification

Wax coated on the surface of the food contact copolymers , PVC coatings, powder coatings, inks and the like.

5 . Plumbing hardware FDA testing and certification of products

And drinking water, faucet water contact , pipes, containers , valves , water heaters , etc.

6 rubber resin FDA testing and certification of products

7 sealant FDA testing and certification

8 . Chemical additives FDA testing and certification

Pigments, preservatives , antioxidants , surfactants and the like

9 , food

10 , the medical device

11 , drug

12 , food additives

13 , drinks

14 , with food-related materials.

ASTM predecessor of the International Society for Testing Materials (International Association for Testing Materials, IATM).

1880s , to address the comments and disagreements buyers and suppliers in the purchase and sale of industrial processes to produce the material , it was proposed to establish technical committee system , the Technical Committee composed of representatives of all aspects of the organization to participate in technical seminars , discussions to resolve the material specification , test procedures and other aspects of contentious issues .

ASTM is one of America’s oldest and largest nonprofit academic standards bodies . After a century of development , ASTM existing 33,669 ( individual and group ) members , of which there are 22,396 members of the main committee as a technical expert working in its various committees. ASTM technical committees under total of 2004 Technical Sub-Committee . There are 105,817 units participated in the ASTM standards development work , the main task is to develop the characteristics and performance standards , test methods and procedures standard materials, products , systems, and services sectors and promote the development and promotion of knowledge .

1 ASTM standard classification

ASTM standards of the following six types.

( 1 ) Standard Test Method (Standard Test Method) it is for the identification, detection and evaluation of material , product, system or service quality , characteristics and parameters and other indicators and the use of prescribed procedures .

( 2 ) Standard Specification (Standard Specification) of its materials, products , systems, or project technical requirements and gives specific instructions , but also to meet the technical requirements of the proposed procedure should be used .

( 3 ) Standard Practice (Standard Practice) it has one or more particular description given operation or function , the process does not produce results .

( 4 ) Standard Terminology (Standard Terminology) describe or define its terms , symbols , abbreviations, Acronyms explained.

( 5 ) Standard Guide (Standard Guide) it has a series of selection or usage is explained , but does not describe the specific implementation methods.

( 6 ) standard classification (Class.fication) it according to their origin , composition, performance, or use of materials, products, systems, or to distinguish and classify specific services

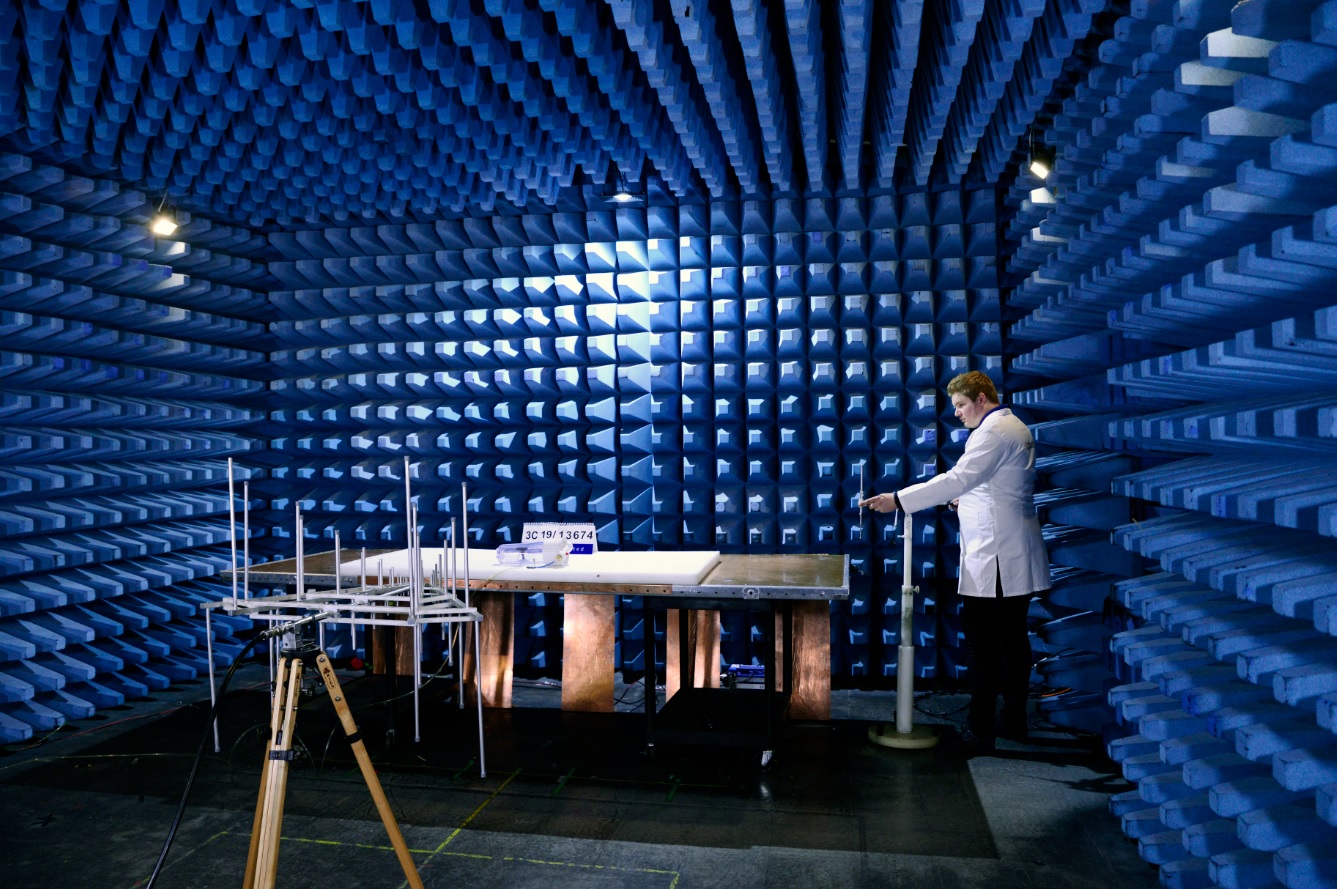

FCC is FEDERAL COMMUNICATIONCOMMISSION ( Federal Communications Commission ) for short. FCC certification is on electromagnetic compatibility testing and certification , the U.S. FCC operating frequency for electromagnetic interference 9KHZ more electronic products are generated by the control . Electrical and electronic products sold in the United States , the need to apply for FCC certification and labeling FCC label .

FCC Certification There are three main ways :

Mainly for products

Self- verification

AV products , corded telephones, common household appliances , commercial PC, industrial consumers FCCRulePart18 non- public use , scientific and medical equipment ;

Declaration of Conformity

Home computer and peripherals,

Civilian radio receiver,

FCCRulePart15 other receivers,

TV interface devices,

Industrial cable system terminal devices and Part18 mass consumer use , scientific and medical equipment ;

Certificate

Low- power transmitters such as cordless phones, automatic door remote control, radio-controlled toys and security alarm systems,

Part15 of intentional radiate radio frequency energy equipment,

Industrial Part18 mass consumer use , scientific and medical equipment , automatic frequency receiver and super-regenerative receiver, the TV interface devices, and home computers and peripherals ;

IAQC support you to get all global verified certification around the world.

All our services around the world done in the minimum time

Ensure Unfettered Access to Lab Resources.

Ensure reliability of your product for longer duration.

Assure safer and secure products.

Advanced drug discovery solutions.

Public Transportation Safety Certification.

Ensure public health and safety for Fast-moving consumer goods.

Ensure food products comply with global guidelines.

Services Safeguard food products, Genetically modified organism.

Copyright © 2021 IAQC - All Rights Reserved